Guide On: Breakout Leads Vs. Back-Pin Probes

Vehicle Diagnostics: Breakout Leads Vs. Back-Pin Probes

Vehicle diagnostics involves measuring power and electrical signals with a Digital Multimeter, Oscilloscope or other test equipment. To make connections to conduct diagnostic tests, technicians often use Back-Pin Probes or specific Connector Breakout Leads to connect to sensors or actuators to gather diagnostic information. Discover below the advantages and disadvantages of both diagnostic connection methods so that you can make an informed judgement on what is more appropriate for the diagnostic tests that you conduct.

2 - What Are The Advantages of Back-Pin Probing?

3 - What Are The Disadvantages of Back-Pin Probing?

4 - What Are The Automotive Connector Breakout Leads?

5 - What Are The Advantages of Vehicle Diagnostic Breakout Leads?

6 - What Are The Disadvantages of Vehicle Diagnostic Breakout Leads?

1. What is Back-Pin Probing?

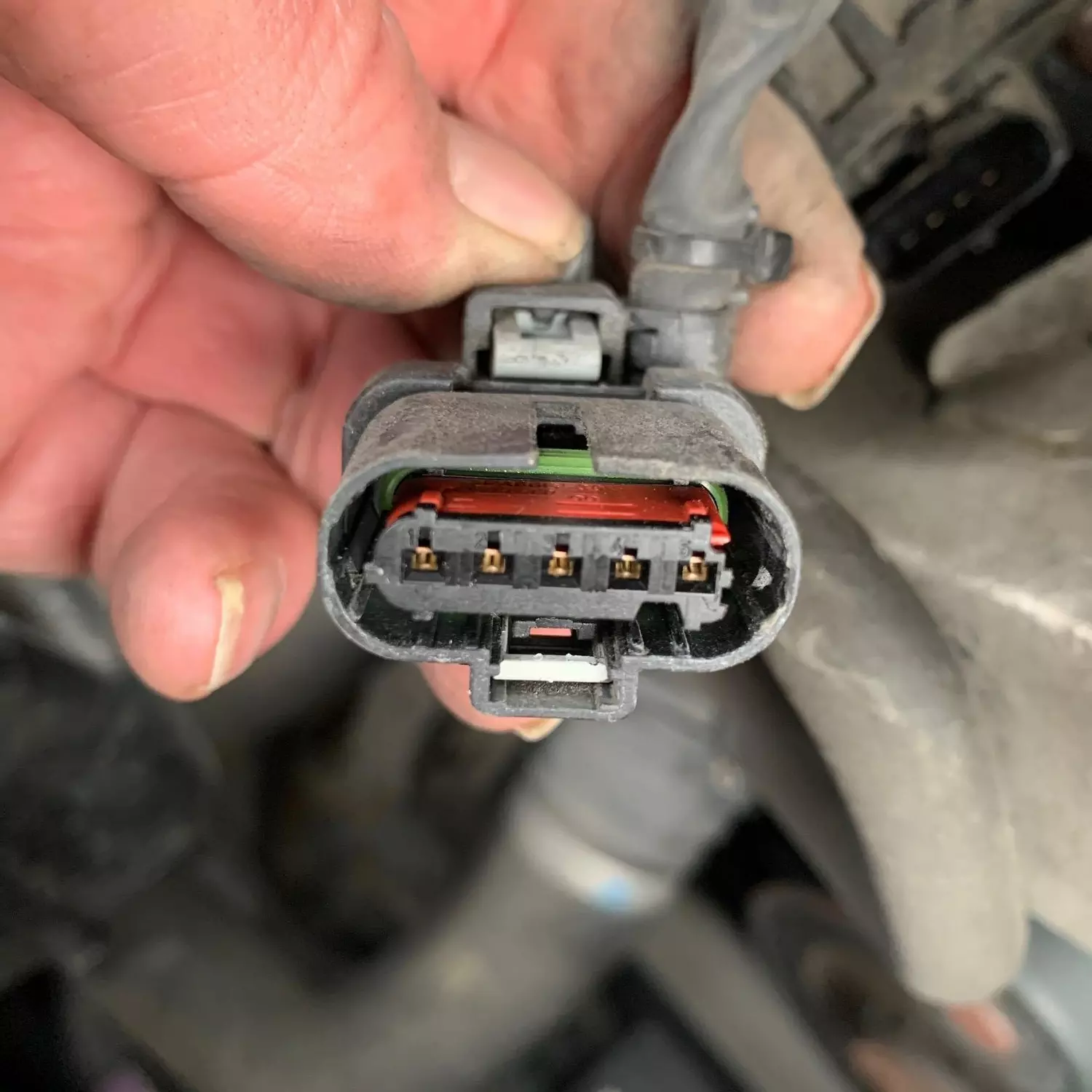

Back-Pin Probing is also referred to as ‘Back-Pinning’ in automotive vehicle diagnostics. A back-pin probe features a sharp pin with a banana jack at the rear that usually accepts a standard 4mm Banana Test Plug. The pin is used to slide past automotive connector seals at the rear of the connector and make contact with the terminal inside the connector housing. Back-probing connector terminals is undertaken when live circuit measurements are required using a multimeter, oscilloscope or other test equipment.

2. What are the Advantages of Back-Pin Probing?

- Back-Pin Probing eliminates the need to puncture or pierce wire insulation to test the circuit. This safe guards wire insulation integrity and prevents comprising vehicle looms performance and longevity.

- Many Back-Pin probes offer the capability to replace broken or damaged pins at the front of the probe. Replacing damaged pins is fairly easy and cost effective preventing the replacement of the whole probe.

- Technicians are able to test and measure a wide range of automotive connectors with Back-Pin probes. Connections are made without the need of specific connector breakouts. They are versatile, cost effective and useful across different vehicle models and manufactures.

3. What are the Disadvantages of Back-Pin Probing?

- If used without care or having test leads attached to the Back Pin can often cause adjacent probes to touch each other, resulting in a short circuit and circuit damage. The damage can be difficult to trace and further complicates the diagnosis. Circuit damage can be costly in added time and loom replacements. Back-pinning may invalidate the manufacturers warranty on wiring looms and connectors. To mitigate warranty complications many use designated breakouts that comply and prevent loom damage.

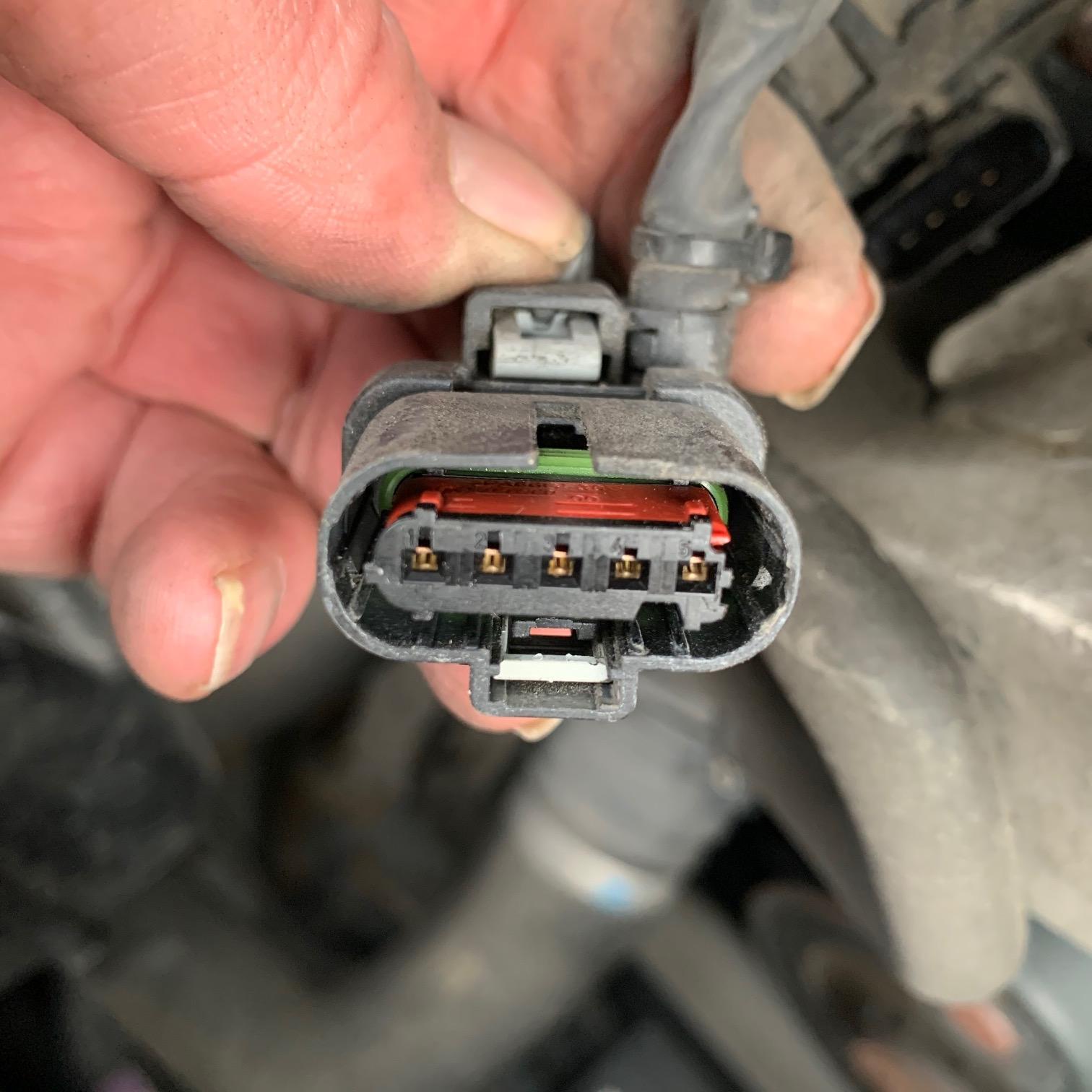

- Back Pinning often damages the weather seals on the connector or the internal terminal. Damage to the weather seals encourages ingress of moisture and dust that leads to corrosion and eventually results in connection and signal failure. New connectors aren’t particularly costly but they can be difficult to accurately identify and source with thousands of variations on the market.

- Back Probing is often associated with unreliable and poor electrical connections. There is high risk of a weak and unreliable connection as the probe is inserted through the back of a connector without certainty of creating a secure and positive connection. It is reliant on touch alone with the amount of pressure/ resistance varying when subjected to vibration etc. Unreliable measurement readings often cause misdiagnosis and unsuccessful fault finding.

- Deploying a back-pin into a connector can be difficult when the connector is difficult to access. This increases the risk of damage or a poor connection.

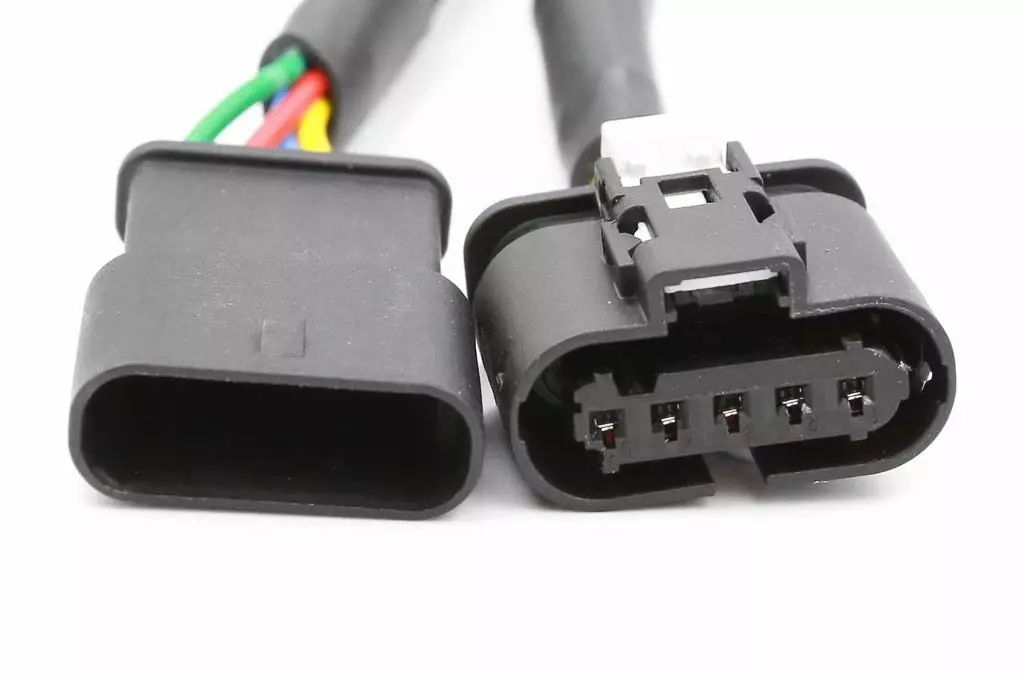

4. What are Automotive Connector Breakout Leads?

Vehicle Connector Breakout Leads feature a male and female automotive connector and shrouded banana test sockets. The breakout leads are designed to connect 'in-line' into an existing vehicle cable loom and the 4mm banana test sockets offer access to connect multimeter or oscilloscope BNC test leads to capture the output signals. The breakout lead cable gives easy access to individual wires and the capability to probe with current clamps (amp clamps).

5. What are the advantages of Vehicle Diagnostic Breakout Leads?

- Breakout leads are designed to create an in-line circuit and offer easy access to output signals and individual wires. Versatile set-up enables technicians to have easy access to diagnose individual wires for voltage and current for specific test and measurement tasks. Readings and waveform capture is fast, effective and reliable.

- Vehicle connector breakouts offer a secure and reliable connection just as the manufacturer had designed. The male plug and female socket locates and connects to the chosen vehicle connector/sensor. The connection simulates the vehicles exact working electrical connection.

- Vehicle Connector Breakout Leads manufactured by Warwick Test Supplies are built in the UK using IEC rated components and OEM connectors offering hard-wearing performance for the workshop.

Breakout Leads By Brand

Discover reliable and hard wearing automotive connector breakout leads compatible with the vehicle brands below;

6. What Are The Disadvantages Of Vehicle Diagnostic Breakout Leads?

- Vehicle Manufacturers use a plethora of different vehicle connectors. There is not a 'one lead fits all' approach, each vehicle connector requires a designated breakout lead. Vehicle Breakout Leads are sold separately or in brand specific kits. A VAG Connector Breakout Lead Kit for example, covers the majority of Volkswagen, Audi and Skoda vehicles.

- Automotive Connector Breakout leads are costly, in comparison to back-pin probes but last exponentially longer. However, fast connections and reliable readings help improve fault finding efficiency, reducing diagnostic labour time and overall costs.

7. Breakout Leads Vs. Back-Pin Probes - Conclusion

Technicians that perform advanced automotive electrical diagnostic tests using oscilloscopes and test equipment rely on; fast, secure and safe connections to perform test and measurement readings. Back-pin probes partly satisfy these needs, but connection security is often questioned and inadvertent damage to either the connector or cable loom circuit is a realistic concern as it can invalidate manufacturers warranty. That said, back-pins are cheap and used correctly can offer a versatile option that can be used on majority of connectors and different vehicles.

Diagnostic breakout leads are fast and easy to connect to vehicle sensors and actuators enabling easy access to wires to test. They provide a secure and reliable connection without compromising connector weather seals, terminals or risk shorting circuits. Breakout leads are a costlier alternative to back-pins, but there functionality and performance is arguable money well spent and their longevity will outlast multiple replacements of back-pins. Many have said they speed up diagnostics and improve working efficiency.